Precision Mold Technology

Molding technology at reduced cost without sacrificing performance.

Plastic lenses have the advantage over glass lenses when a lower cost is required. Yet plastic lenses are likely to have problems resulted from molding such as deformation and low precision that reduce their competitiveness versus glass lenses. However, Ricoh has succeeded in molding plastic lenses with large sizes, good deflection and thickness and also having none of the deformation or accuracy problems that occur in conventional injection molding. Ricoh has accomplished this method by an in-house developed method called "Gate Seal TM molding". This is a gentle and natural molding method for plastic lenses that does not require complex control methods or mold structures and yet allows molding plastic lenses easily to have a high precision rivalling that of glass lenses.

Overall View

1.Injection Molding

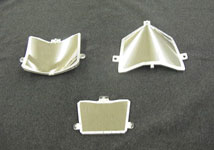

Based on long years of accumulated experiences and know-how in this field along with the in-house technologies, such as injection compression, low pressurized molding, shape compensation, and temperature control, RICOH Industrial Solutions Inc. has accomplished in adding high precision molding quality to products such as long scale lenses, f-theta lenses, prisms, large diameter projection lenses, aspherical mirror, as well as compact projection lenses and prism.

2.Remelt Molding

The relentless pursuit for advanced molding technology by RICOH Industrial Solutions Inc. has made it possible to establish Gate SealTM molding technology, which is characterized by high precision and low birefringence. This has evolved further to establish yet anothertechnology called Remelt molding process, which provides new possibility to manufacture larger size molded products with increased molding efficiency. As a result, Ricoh has opened the way to produce molded f-theta lens with similar range of precision as glass lens, and also the f-theta mirror, which requires even higher precision than lens.

3.Molding for Hybrid-Lens

Hybrid-lens is an aspherical lens made by depositing layers of thin UV-cured resin on top of spherical glass lens. With its larger diameter and higher precision never acquired before, hybrid-lens is a significant contributor on making compact size and high precision projection lens for a projector.

Additional time may be needed to respond to mail received on or immediately before or after weekends, holidays, or the year end/New Year's. We apologize for any inconvenience this may cause.